Business

Hungary to become battery producing "superpower"

Hungary wins major EV battery production

Ceauto.co reported on 21 November that SK Innovation, which owns South Korea’s top refiner SK Energy, plans to build its first European battery plant in Komárom, northwest Hungary.The planned investment, however, was not picked up by Hungarian press until Portfolio reported about it this Tuesday.

SK Innovation released a statement the same day, denying that a final decision has been made on the location of the new plant.

Yet, according to the environmental protection documentation of the project displayed in the building of the municipality of Komárom, SK Innovation plans to launch construction of its new plant in February 2018, start a trial run in the summer of 2019 and switch to mass production in January 2020. In the first phase, SK Innovation would build on 66,000 square metres in the industrial park, adjacent to Poland’s Alumetal.

On Thursday, the company has confirmed the decision to set up shop in Komárom.

SK Innovation

- decided to invest more than 1 billion won (USD 925 million) to boost electric vehicle (EV) battery production capacity to meet growing demand;

- will invest 840.2 billion won (USD 777 mn) to build a battery plant in Komárom, northwest Hungary;

- plans to break ground in February 2018 and

- start production from early 2020;

- in the 430,000-square-metre plant;

- with a planned capacity of producing EV cells with a combined 7.5 gigawatt hours (GWh) per year.

Electric vehicles powered by South Korean batteries have been excluded from state subsidies in China, Reuters noted.

SK Innovation has suspended an EV battery pack plant in China with China's Beijing Automotive Group and Beijing Electronics, and had also delayed a plan to build an EV battery cell factory in China, it added.

Komárom is home to assembly lines of German carmaker Audi and is not far away from a plant of another German automaker, Daimler, which owns Mercedes-Benz, Yonhap News Agency reported.

SKI Innovation to expand existing production capacities

SK Innovation has also made a decision to invest about 150 billion won to expand production capacity of lithium-ion battery separators, a key component in EV batteries, in Jeungpyeong, about 126 kilometers south of Seoul.It also announced a plan to expand EV battery production lines in Seosan, 150 kilometers south of Seoul. The latest investment will raise domestic production capacity of EV cells to a combined 4.7 GWh.

Batteries to be produced in the new facility in Seosan could enable a car to travel 500 kilometers -- the distance between New York and Plattsburgh -- on a single charge, according to the company.

SK Innovation is South Korea's top oil refiner, but it has been pushing into the EV battery business since 2008 as part of efforts to find new revenue sources.

A very serious producer

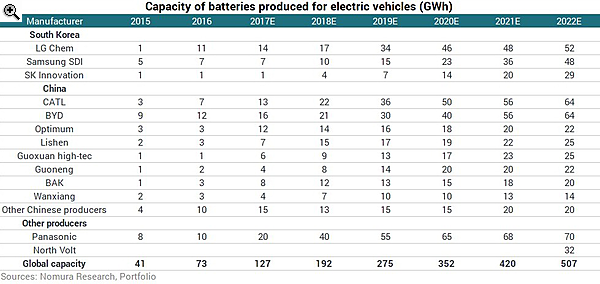

SK Innovation is already one of the key players in the manufacturing of batteries for e-cars. Its output capacity is expected to reach 3.9 gigawatt hours by 2018 with a view to dynamically increase this figure in the coming years, close to 29GWh by the end of 2022.

South Korean producers spring up like mushrooms in the region

With the latest entry of Korea’s third biggest battery maker, Hungary will now host the production facilities of the nation’s top three battery makers, including Samsung SDI and LG Chem.LG Chem is scheduled to open Europe’s largest lithium-ion battery factory in Poland next year. LG Chem, a subsidiary of Korea’s LG Corp, plans to spend 5.9 billion zlotys (USD 1.63 billion) on the plant near the southwestern city of Wroclaw, according to Polish state industry agency ARP. The company expects to produce up to 100,000 EV batteries in Poland annually from next year, and the plant will employ 2,500 people.

LG Chem did not name the likely customers but said they would include top car companies. It was not immediately clear if the factory would produce all the basic battery cells from scratch or import some components, but the statement said the site would include a research and development centre employing “about 400 engineers from various specializations: automation, electronics, chemistry and IT", Reuters reported in mid-October.

Samsung SDI celebrated the completion of construction of its EV battery plant in Göd, 30 kilometres north of Budapest, on 29 May this year. The company’s HUF 100 billion facility, sprawling on a 330,000-sqm site, will create 600 new jobs. Operations are expected to start in the second quarter of 2018. Once at full capacity, the Göd factory will be able to produce batteries for 50,000 electric vehicles annually. Samsung had built the plant in 2001 that is now being reconstructed to host battery manufacturing.

Once they smell blood...

The flocking of South Korean battery makers to the region is not a coincidence. European carmakers announced one after another that they would launch a host of new or partly new e-cars in the coming years, while they do not have their own battery production capacities. Consequently, they must import batteries from China or South Korea. And as demand is likely to rise, South Korean manufacturers come and settle down in Europe.European carmakers naturally want to remedy the current situation and keep announcing (with quite a delay) that they would start their own battery production. In Germany, they have set up TerraE-Holding GmbH to handle planning for building large-scale lithium ion battery cell manufacturing in Germany. The consortium comprises 17 major companies and research institutions. Production by the “Gigafactory" is expected to start in Q4 2019. The goal is to gradually build up production capacities of up to 34 GWh/year by the year 2028. The consortium will address industrial and electromobility with different cell formats.

Sweden’s NorthVolt AB, founded by former Tesla executive (head of sourcing and supply chains) Peter Carlsson, plans to start battery production in Sweden and Finland. NorthVolt’s initial facility in Sweden is planned to have capacity to produce about 8 gigawatt-hours of batteries per year, rising to 32 gigawatt-hours once the project is fully operational in about six years. The company expects to lower to cost of lithium-ion battery packs significantly, aiming to halve prices by 2022, Carlsson said.

Electromobility to be increasingly crucial for Komárom

BYD, the world’s largest electric bus producer, opened its new facility in Komárom this April. In the three years to 2018, the company’s investment will total some EUR 20 mn (HUF 6.2 bn) and eventually the plant will employ 300 workers to assemble up to 400 e-buses annually in two shifts. The cabinet provided a non-refundable subsidy of HUF 925 bn for the project.The Komárom unit of BYD, a company listed on the Hong Kong Stock Exchange and the Shenzhen Stock Exchange, will initially assemble electric city buses and coaches for European orders. There are plans to produce bus chassis for buses to be assembled into complete vehicles in co-operation with UK company ADL.

BYD also plans to manufacture bus chassis for a recently announced BYD plant in France, and also to assemble electric forklift trucks and light commercial vehicles at the Komárom unit later on.

The planned capacity of SK Innovation combined with the capacity of Samsung SDI in Göd would make Hungary the largest battery manufacturer in Europe by 2020. The establishment of the new EV battery plant is excellent news for the country, since the product is likely to be needed even 10 or 20 years from now. SK Innovation will not only bring funds to Hungary but it will also create jobs. At the same time, we need to highlight that we still have no information whether the Komárom facility will be only an assembly unit or it will also feature research and development. In view of the sum to be invested, we have a strong feeling that in the first few years it will be offering only assembly work.

In that case, though, this will be only another “Made in Hungary" deal, i.e. it will be just assembly/production, while the cabinet wants to take steps towards the “Invented in Hungary" label, i.e. towards local development.

In that case, though, this will be only another “Made in Hungary" deal, i.e. it will be just assembly/production, while the cabinet wants to take steps towards the “Invented in Hungary" label, i.e. towards local development.